Strong Chemical Bonding

Our process uses tailored and controlled oxidation to create powerful chemical bonds at the molecular level. Thanks to the high surface activity of nano-ceramic particles, the coating forms a strong oxidative bond with the substrate. This significantly outperforms traditional mechanical adhesion methods. The coating delivers exceptional durability and adhesion across a wide range of materials, including metals, ceramics, glass, plastics, and composites.

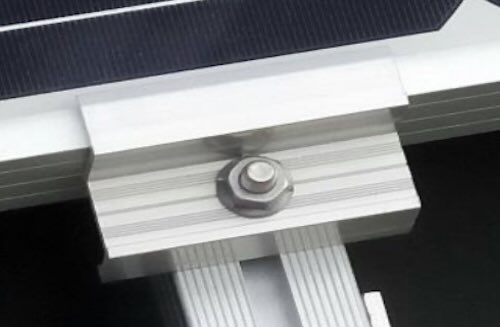

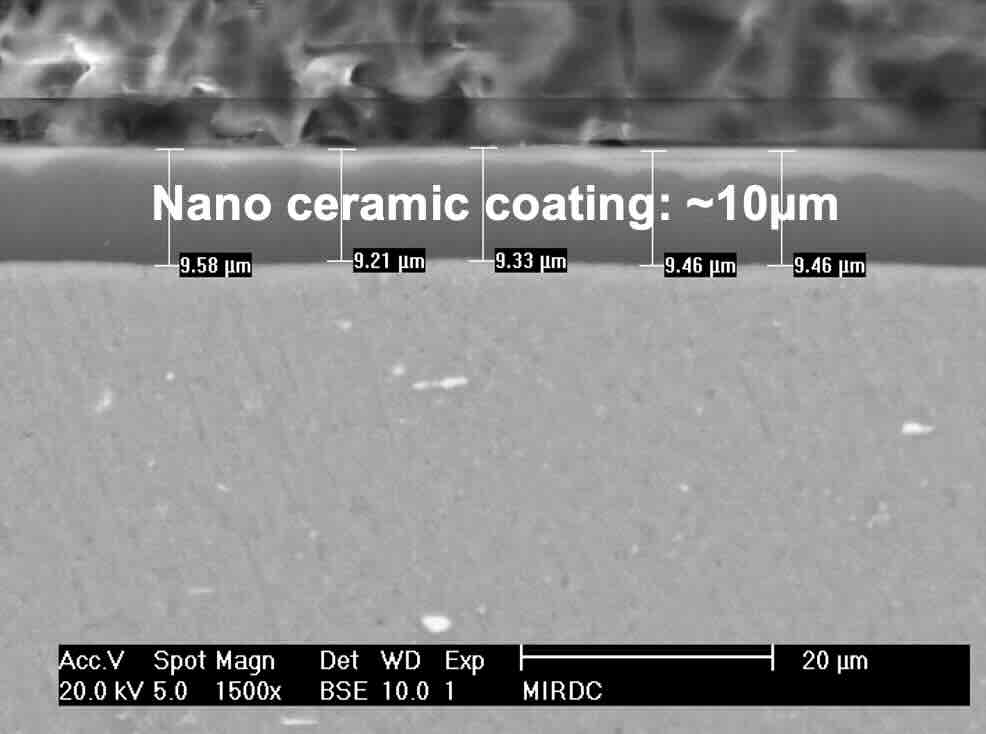

Ultra Thin Shielding

With a film only 10 microns thick, our coating provides up to 1,000 hours of red rust protection. The TrueECO solution delivers reliable corrosion resistance while keeping recess fill to a minimum, making it ideal for precision components like M1 screws.