TrueEco Technology uses molecular engineering to make precise combination of oxide ceramics and organic polymers in nano scale, thereby combining the excellent performance of ceramics and the ductility and toughness of resin. This nano molecule has extremely strong chemical activity, and can form direct chemical bonds with various metals, glasses, ceramics, plastics, composites, etc.

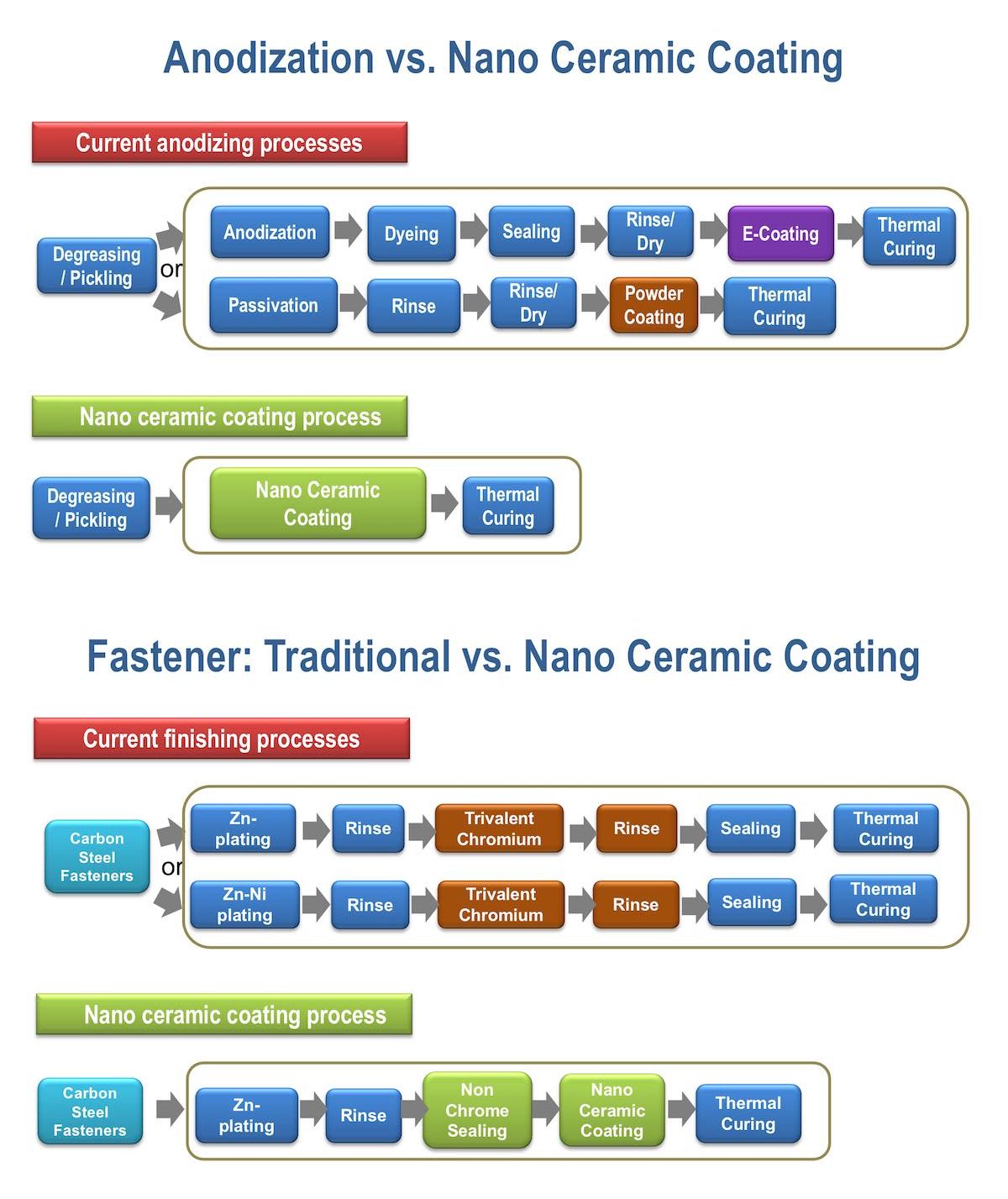

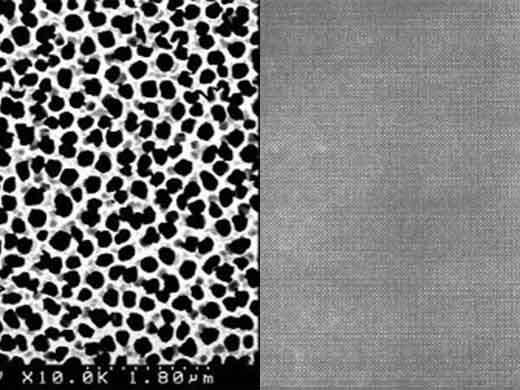

The traditional metal surface treatment must produce high porosity, so that the coating can have a good adhesion. For example, most of the aluminum materials used for semiconductor parts or equipment in the clean-room are anodized, which will easily cause particle contamination in such environment.

Nano ceramic coating does not need pores and pre-treatment, and can directly produce strong adhesion by chemical bonding, reducing the contamination caused by anodizing. In addition, it does not affect heat dissipation with its ultra thin film thickness (5-8 μ m).